Grain Temp Guard – 1st Generation

$275.00 – $2,200.00Introducing our Unbeatable Closeout Prices for the Revolutionary First Generation Grain Temp Guards!

We are thrilled to announce that we have recently upgraded our Grain Temp Guard lineup with the next generation of bin monitors. To make room for these cutting-edge models, we are offering unbeatable closeout prices on our first-generation units.

What sets the first generation apart? These Grain Temp Guards boast an impressive error rate of just 2% in their readings. However, with our new and improved next-generation models achieving an even lower error rate of 1%, we are eager to clear out our remaining first-generation stock.

Not sure which model to order? Our Grain Temp Guards are available in two variants:

-

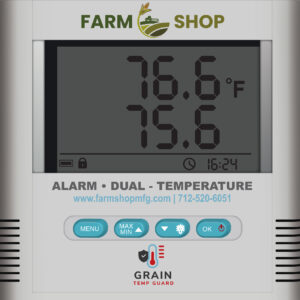

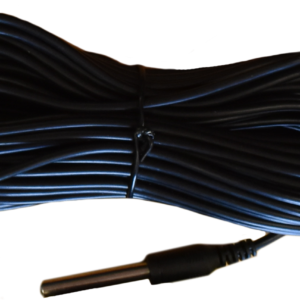

Dual Temp (DT): This model is equipped with probes strategically placed at two locations within your grain bin. By monitoring temperature variations across your grain, it provides valuable insights into potential hot spots.

-

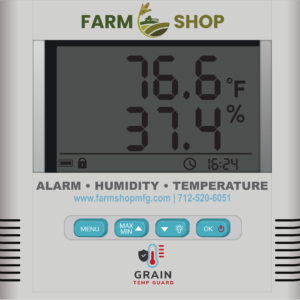

Humidity Temp (HT): With a single probe placed at a specific location in your bin, this model allows you to monitor both temperature change and humidity levels at that particular spot, tracking moisture and moisture migration in your bin.

The Grain Temp Guard is ideal for bins with a capacity of 20,000 bushels or less. If you have a larger bin, simply purchase an additional probe for every additional 10,000 bushels to ensure comprehensive monitoring.

For enhanced grain monitoring capabilities, consider bundling multiple DT and HT systems. This will unlock a host of benefits and elevate your grain monitoring plan to new heights.

The Grain Temp Guard system gives you valuable knowledge about your grain bin, enabling you to develop a personalized monitoring plan. Say goodbye to waiting until it’s too late to address issues. Stay proactive by detecting problems early and safeguard your grain effectively.