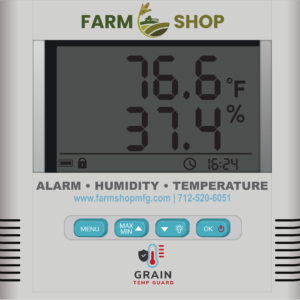

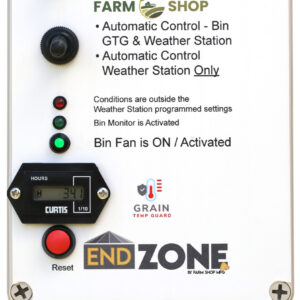

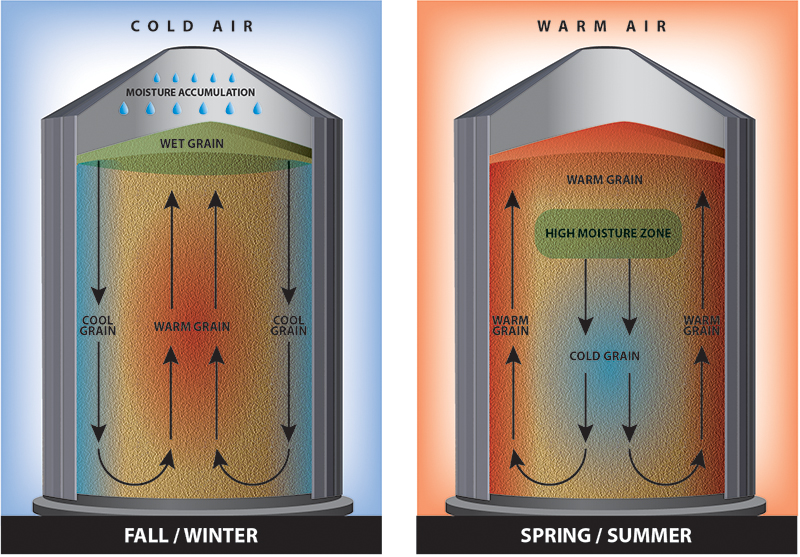

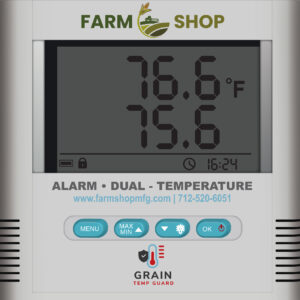

The Grain Temp Guard Humidity-Temperature system is ideal for monitoring higher moisture grains or grain you are conditioning. Track grain conditioning with the humidity reading and data charts from our resources page. High and low temp/humidity warnings may be set independently on each function. Audible and visual alarm sounds when detecting changes in target temperature/humidity. The Grain Temp Guard Dual Temperature System is ideal for monitoring conditioned grains. Measure temperature in two distinct locations. High and low temp warnings may be set independently on each probe.

Grain Temp Guard

- Sealed poly case with polycarbonate clear cover for easy visualization

- Easy to open latch style cover for setting

- 110 V external power with internal battery backup

- Visual and audio alarm on a 10 m cord for mounting in a more accessible area

- 15m Probes come standard with the unit

- Additional probe lengths available: 10 m, 15 m, 25 m, 30 m and 45 m

- Monitor temperature and humidity at one location in the grain bin

- A must-have for conditioning grain (utilizing fans to lower grain moisture)

- Trigger visual and audio alarm based on a high and low trigger point set by the operator for temperature and humidity

Over-drying corn or beans reduce your product by 1 1/2% for each 1% moisture loss.

Based on current prices, in a 30,000 bushel bin this costs:

$1650 for corn

$3850 for beans

Money spent to put an alarm HT probe in the top (this can be placed after the bin is full) of the bin and one in the bottom would go a long way to help a farmer get control of this.

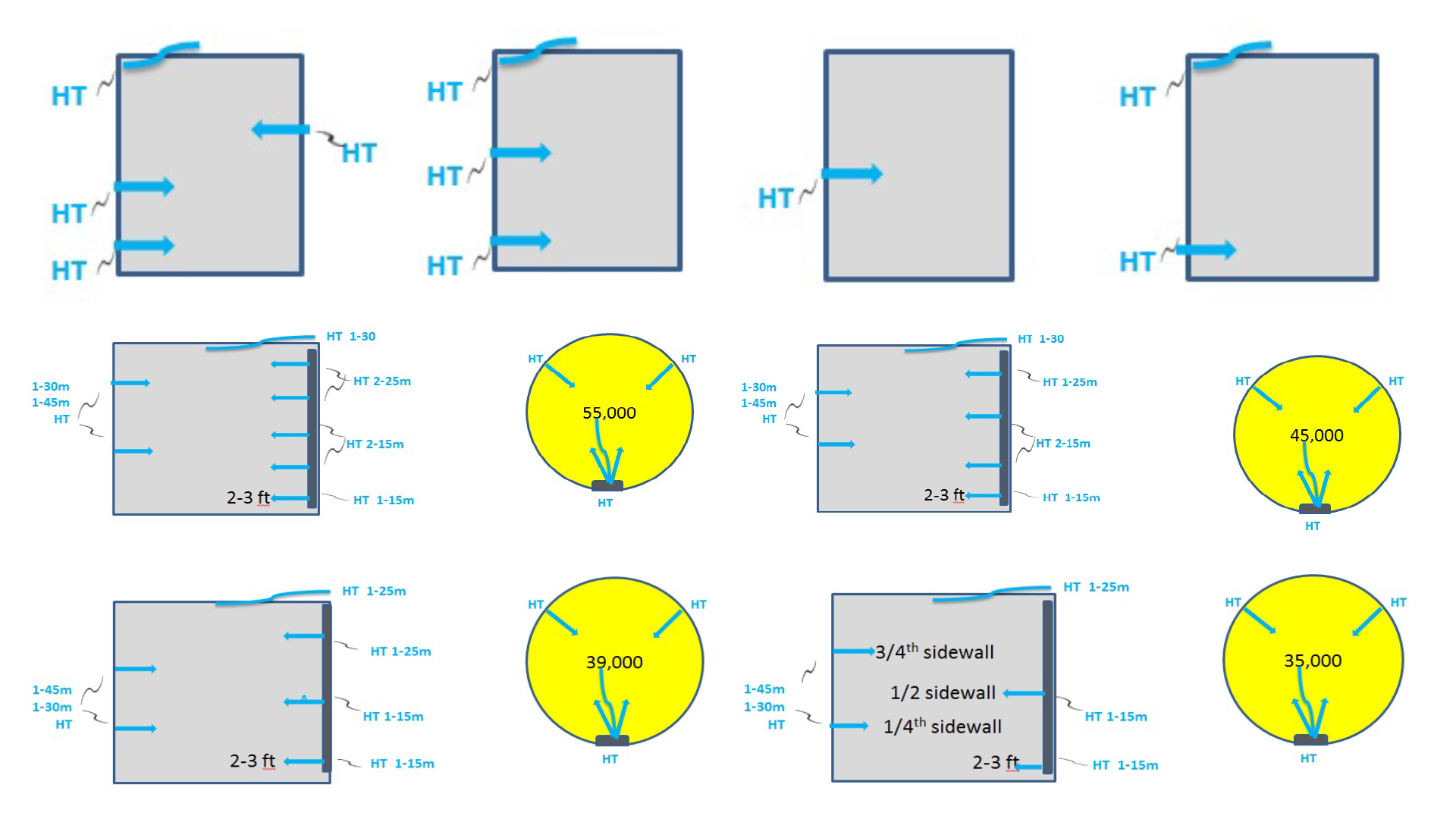

Recommendations for the number of probes to consider for your bin

Recommended: 2 probes per bin for the first 10,000 to 20,000 bushels and 1 additional probe for each additional 10,000 to 15,000 bushels. This will allow you to monitor more layers through the bin.

When using the Alarm HT (the correct unit for monitoring bins in which you are doing in bin drying or for monitoring soybeans) you will need to purchase twice as many units because this device has only 1 cable per monitoring unit. It is using its function to monitor both temperature and humidity (humidity is the key to providing the best grain moisture solution).