Germinator Install Instructions

Install Instructions

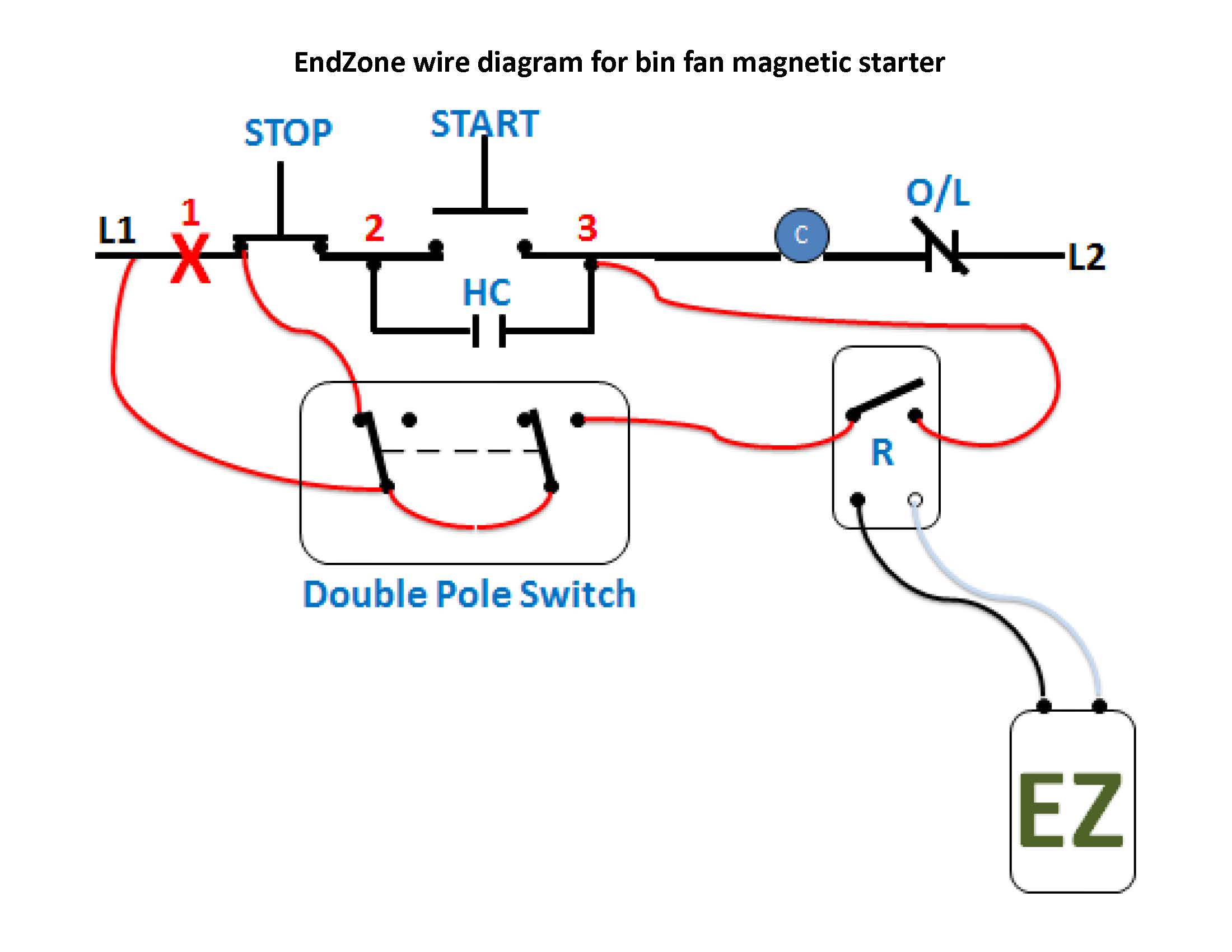

EndZone Fan Bin Magnetic Starter

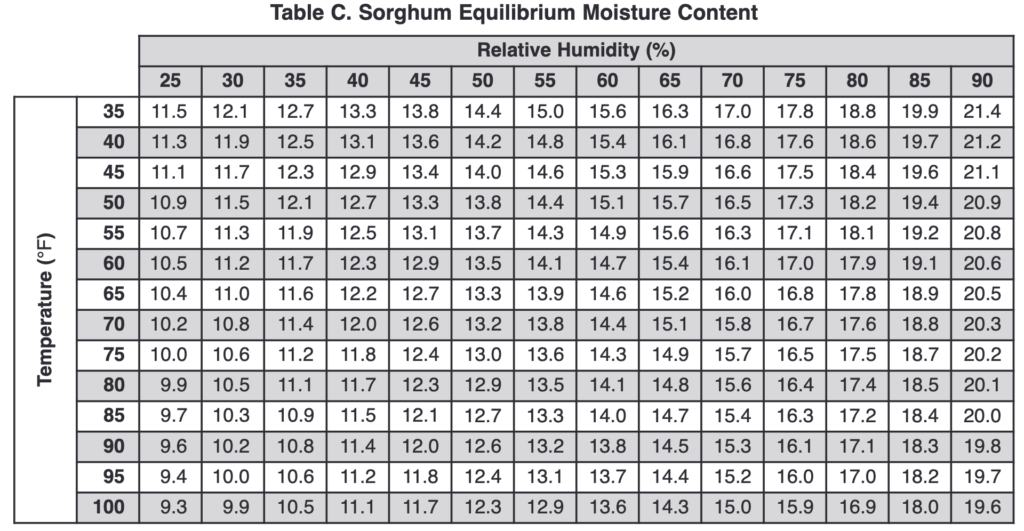

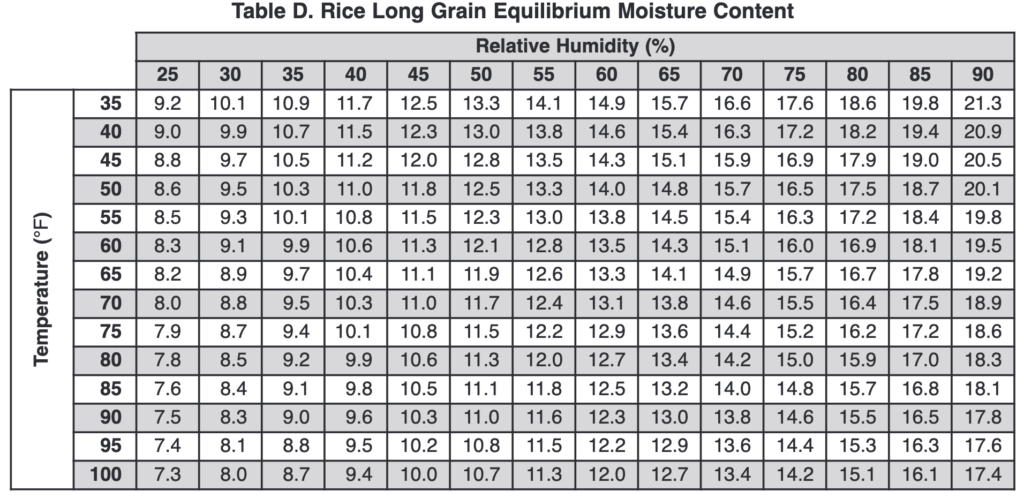

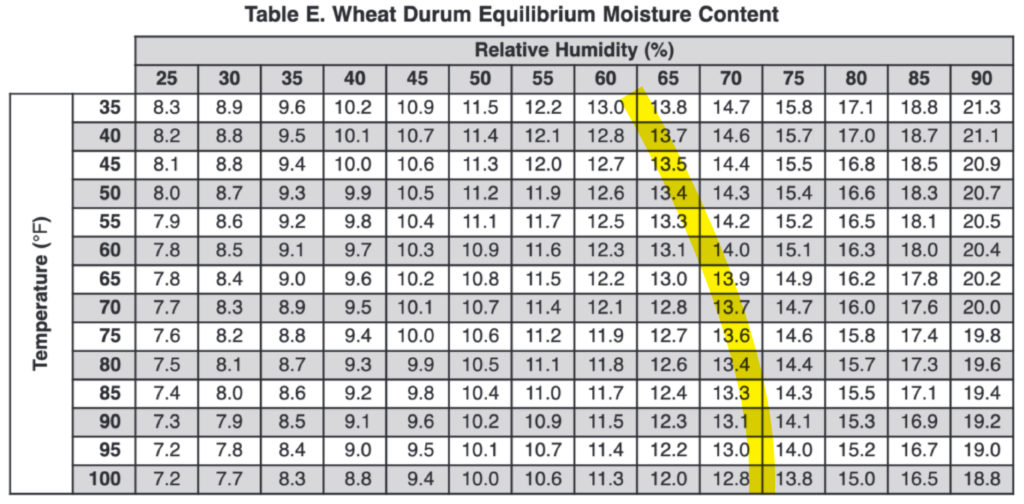

Moisture Content

Moisture Content

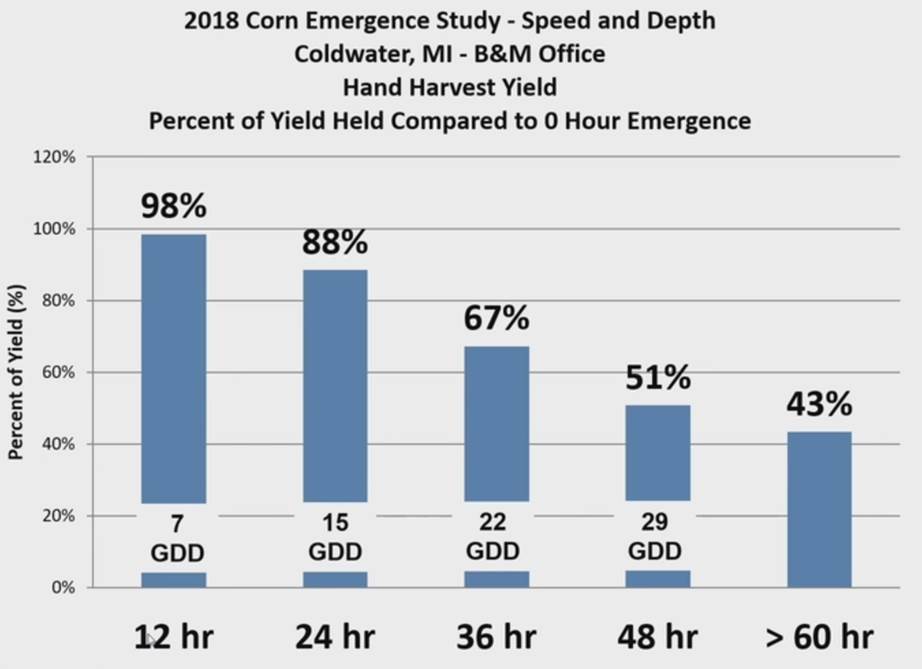

Uniform Emergence

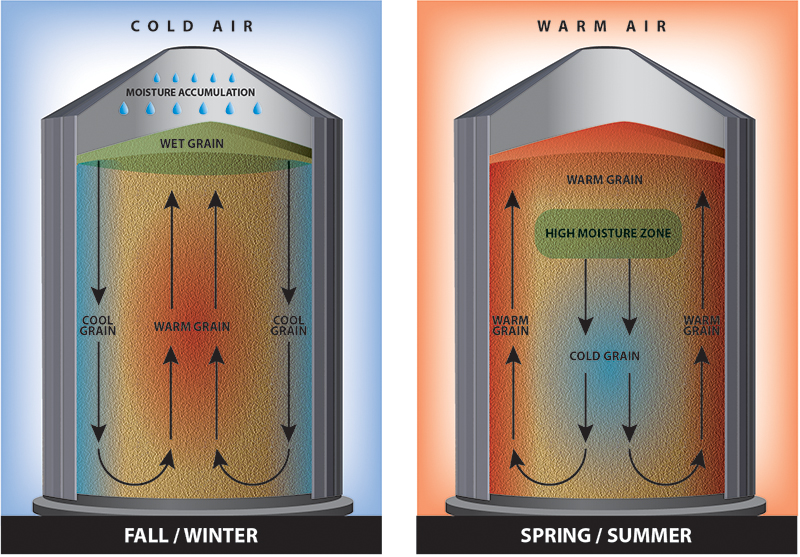

Moisture Migration

Because grain is a good insulator, the center of the grain bin retains heat longer. Moisture migration is caused by differences in grain temperatures within the bin. In the Fall, the cold air on the outside of the bin moves the warmer air inward and eventually upward to the top of the bin. It encounters the cold air at the top of the bin and causes condensation and crusting at the top of the grain. In spring and summer, the opposite is true and condensation and spoilage occur at the bottom of the bin. Temperature monitoring helps maintain even temperature, preventing moisture migration.

Why Use Temperature Monitoring

- Have access to accurate information about storage conditions

- Make sure your aeration systems are energy efficient

- Keeps your grain at the best quality possible

- Alerts you to susceptibility of mold growth due to changing conditions

Grain Temperature Monitoring

Temperature is the best indicator of grain quality. When there’s a significant drop in grain quality, there’s alway an abnormal increase in grain temperature. Excessive moisture, high temperature, and poor grain condition often lead to trouble in stored grain. The importance of monitoring these aspects is compounded by the fact that grain is now stored longer and in larger bins than before. Harvesting and storing grain at a higher moisture content and the higher cost of handling and moving grain also increases the risk of problems. By monitoring temperature accurately, grain only needs to be turned when required. This makes aeration systems more efficient.

Grain is a perishable commodity and will only last so long. It loses its quality faster as temperature and moisture increase. Monitoring temperature and humidity helps grain maintain its market grade status for a longer period of time.

On the opposite end of the spectrum, temperature and humidity monitoring can prevent the overuse of aeration systems that leads to shrinkage. Over drying by 2-4% can cause significant bushel loss per bin resulting in thousands to tens of thousands of dollars in lost profits.