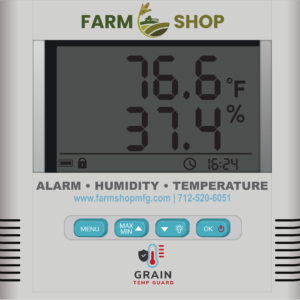

1. The location on the bin where you would like to position the unit. Do not position the unit in a location on the south or southwest side of the bin where afternoon sun will shine directly at the electronics (direct sunshine into the polycarbonate clear cover will result in a greenhouse type solar heating and can increase the internal temperature by 35°F to 50°F as compared to outside environment, thereby damaging the electronics). If you position the unit on the south or southwest side, it needs to be in a shaded area. Failure to do this will damage the LED screen and void the warranty. Additionally, you may want to consider an area in proximity to the internal ladder, as we normally use this structure to zip tie the cable to. Any loose cable on the outside the bin needs to be zip tied to a structure such as conduit, ladder rails, etc. to prevent wind whipping and chafing of the insulation. It is not recommended that you have long lengths of exposed cable on the outside of the bin. If this is necessary, it is recommended that you place the cable inside a conduit.

2. Mount the case to the bin; mounting flanges may be adjusted for the best match to a corrugation rib. Remove the gasket from the self-tapping screws, insert the screw through the flanged hole and replace the gasket. The gasket needs to be against the bin to prevent leakage.

3. The probe will require a three-quarter inch hole through the corrugation.

4. Suspend any loose cable within the bin by zip tying it frequently to conduit or sliding it through conduit.

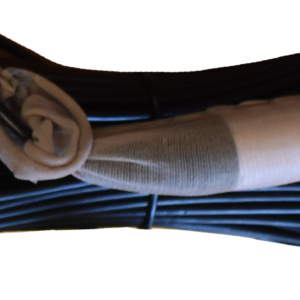

5. A short arm can be made to suspend the lower cable 36 to 48 inches from the ladder by bending a piece of re-rod into an L and positioning the long leg inside a ladder angle iron in the short leg sticking out no more than a foot. Too long of a lever will be ripped off by corn pressure. The long leg should pass behind two ladder rungs and in front of the third (see above graphic) to ensure the mechanism functions properly. Zip tie the long leg of the L frequently or bolt it to ensure strength.

6. Zip tie short cable to the L and zip tie any excess cable in a loop firmly to the ladder structure.

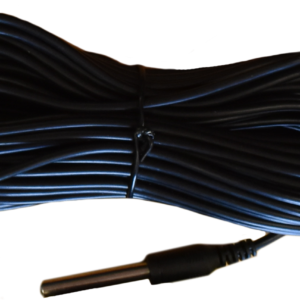

7. Extend the long cable up along the ladder making a small loop of the excess cable and securing it to the top of the ladder or on a hook just below the access hatch. When the bin is full you will take this cable, uncoil it and position it in the grain where you would like to monitor the temperature or temperature – humidity.

The intent of this installation is to keep everything simple and cost-effective. You may at your own discretion provide a more complexed installation.