ADD TO YOUR BOTTOM LINE

About EndZone

Add an extra semi load to your bottom line with EndZone. Play offense and rehydrate soybeans from 10% to 13%. Play defense and monitor and control hot spots in your bin. Use with the complete Farm Shop Moisture Management System and score big.

The Ideal Bin

The ideal bin should have a fan capacity of 1hp per 1,000bu of grain. 1/2hp per 1,000bu will work but will take twice as long. Less than that is not recommended. Ideal grain depth is 25ft or less with a max of 30ft. Grain bin capacity should be 3,000-45,000bu. Talk to Tony before ordering for larger bin.

DESIGNED BY FARMERS FOR FARMERS

The EndZone Difference

EndZone is a super tool for efficient, cost-effective grain management. How often have you wanted to turn a grain bin fan back off because the temperature had dropped too low or perhaps got too high? More importantly, the humidity has risen too high so that you are just wasting electricity (considering all monthly access, meter fees and electrical charges, it costs over $17 to operate a 10 hp fan for 12 hours on my farm), or even worse adding moisture to a crop you were attempting to dry.

Have you ever thought about why the corn in the bottom of your bin is typically over-dried as compared to your target; this is the result of running the fans on a day when the humidity was far lower than the target moisture required.

When low-humidity air enters the floor of the bin, it dries the first grain it comes too with no regard as to what your objective is. With corn, it will irreversibly lower the moisture to an equilibrium balance relative humidity around the grain. At a 65° temperature and 50% relative humidity content on outside air, the grain in the bottom of the bin will be dried to 12% moisture (an excess loss of 3.5% moisture content). It is very difficult to add moisture back to corn, so once over-dried, you will suffer shrinkage loss. For each 1% moisture loss, you have reduced your weight by approximately 1.2%. Based on $4 corn (a round number for easy calculation), this equates to a nickel per bushel or almost $50 per truck load. More often than not, when grain is over dried it is not just one percentage point. It is typically two or three percentage points or more, costing $100-$200 per truckload. If an entire 20,000-bushel bin of corn were over-dried by 2 ½ points of moisture, this would approximate $2500.

Quick Calculation for Value

- 20,000 bushels of soybeans (or wheat) at 10% moisture.

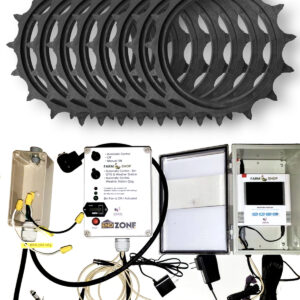

- The EndZone™ system equipment is installed on the bin. The typical cost for a 20,000 bushel bin is $3800 and is made to be farmer-friendly/farmer-installed.

- System is set to increase grain moisture to 13% (ideal maximum selling moisture). Depending on fan size and atmospheric humidity conditions, this may take a few weeks to a few months.

- Soybeans take on moisture, increasing to approximately 13%, increasing the grain volume by one semi load, 54,000 pounds of water.

- In today’s soybean market, this is an additional $12,600 in revenue.

Producers may want to recondition soybeans harvested at lower moisture content to bring the moisture up to the market standard of 13%. On a 40-bushel-per-acre yield, harvesting soybeans at 9% moisture content, rather than 13%, is equal to 1.8 bushels of lost weight per acre. At $9 per bushel, that is $16.20 per acre.

Just as grain is dried with bin fans, soybeans can be reconditioned by operating fans during periods with the desired air temperature and relative humidity. Reconditioning requires high airflow rates for several weeks using air with an average relative humidity of about 70% to recondition soybeans to 13% during normal fall temperatures of 30°F to 60°F. Read More

Kenneth Hellevang PhD, Extension Agricultural Engineer

North Dakota State University

ADD TO YOUR BOTTOM LINE

EndZone

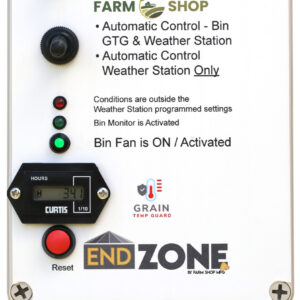

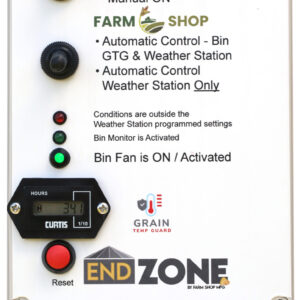

How Does EndZone Work?

Managing a Condition Bin:

Once your grain has been cooled or warmed up to the desired storage temperature, from time to time it is appropriate to ventilate the grain to break up confections that naturally occur within the stored column. EndZone can be set only ventilate with air that is of an appropriate temperature and humidity to not create issues with in the stored grain. It will turn the fans off if the day temperatures and or humidity get too high or too low for the desired outcome as set by the grain storage manager. When weather conditions have returned to the program to parameters, the fans will be reactivated. EndZone can be connected with a Grain Temp Guard® and Activate fans if a hotspot is detected. In the case of an Alarm HT, EndZone can activate the fans if abnormal moisture migration has occurred triggering an alarm setting.

Drying Corn (Crops):

EndZone can be set to “only ventilate” with outside air when conditions are appropriate for generating the drying objectives you are looking for. Refer to the appropriate chart here. Set the devices so that the fans shut off if the temperature and humidity swing to the left side of the chart resulting in over-drying. I personally turn the fans off of the temperature gets too high or the humidity gets too low both resulting in excess moisture removal. On the top side, monitor the moisture and relative humidity within the upper grain column and activate your fans whenever you have a 2 to 4% relative humidity advantage when looking at the right side of the chart. My corn currently is at 20% moisture and after I warm up to 65°, I will run the fans whenever the relative humidity is at around 86% to 87% or 3 to 4 points lower than the humidity within the grain column, also considering current temperature conditions. As your grain is drying, lower the top and relative humidity at which you are going to allow the fan to operate. With three, four, or five points of moisture that need to be removed, you can be a little bolder with your settings, and as you near your target, be more precise. *Periodically monitor your hour meter and measurements resulting from temperature and humidity within the grain column. If weather conditions are such that the control has not run for an extended period of time, closely monitor the stored grain and perhaps periodically turn the fans on for a short period of time. You have a lot of money inside that bin, there is nothing wrong with being a little scared/nervous. Channel it to the appropriate management.

Adding Moisture (Soybeans):

EndZone can be used to activate the fans when outside air conditions will allow for increasing the relative humidity around the stored grain. Refer to the Soybean equilibrium moisture content chart at farmshopmfg.com/resources . Run the fan whenever the relative humidity of outside air is above the charted bean moisture and at not to an extreme level. Do not run the fans when relative humidity % exceeds the upper 80s. Running the fans with to high outside relative humidity will result in the beans at the bottom of the bin rapidly over swelling, plugging the floor. This will result in very limited or no airflow and can cause a potential large problem. When dealing with 9% moisture beans, I ran my fans when-ever the relative humidity was between 55% and 85% and increased the lower setting as the moisture increased. When the grain moisture was nearing the desired target, I also lowered the top end of the range trying to keep my parameters closer to a relative humidity of 70%. Ultimately you need to closely monitor the relative humidity inside the grain column to determine your results. In my experience, I typically ran the fans in the evening or at night and/or early in the morning. When the fans were being shut off, I would see a higher relative humidity inside the grain column and this would decline over the next few hours as the beans sucked the moisture out of the air. This two steps forward one step back type of advance continued until I got my beans close to the desired moisture.

Do not shut the fans off if you have a large temperature gradient between grain at different levels in the bin. You have frozen the grain at the start of winter and now you need to warm it up to 65° to properly dry the grain. In my current bins, the grain is stored at around 25° and when I warm it to 65°, turning the fans off will result in moisture condensation (think about a cold beverage can on a humid day) onto the cold corn above, creating a rot/mold line if the fans remained off for any extended period of time. I like to look for an average temp that brackets my target and leave the fans on until the warming front has traveled clear to the top. After this is completed I will go to work on my grain.

EndZone is a tool that can make your life easier and your outcomes more precise. It does not have a brain, and requires periodic monitoring. Occasionally (for me this is daily), look at your hour meter and the results that are occurring within the stored grain column.

Complete Moisture Management System for a large bin.

Wires can be run into the bin and then through conduit to protect the moisture management system.

Wires can be run though conduit and then attached to rebar to keep everything organized.

Rebar can be used to place sensors throughout the bin at appropriate levels.

Mount lower probe to rebar and place 2ft off ground, attaching to ladder.

Probe for top of bin can be coiled when not in use.

Attach probe to rebar to extend into bin. (Attach to bottom of bar to avoid probe damage)

Attach probe to rebar to extend into bin.

pair with endzone

Moisture Management System Layout

System and probe placement per bin size

- 3,000 to 6,000 bushel bin: 1 EndZone, 1 Grain Temp Guard® Alarm HT

- 7,000 to 15,000 bushel bin: 1 EndZone, 2 Grain Temp Guard® Alarm HT

- 16,000 to 23,000 bushel bin: 1 EndZone, 3 Grain Temp Guard® Alarm HT

- 24,000 to 30,000 bushel bin: 1 EndZone, 4 Grain Temp Guard® Alarm HT

- 31,000 to 37,000 bushel bin: 1 EndZone, 5 Grain Temp Guard® Alarm HT

- 38,000 to 44,000 bushel bin: 1 EndZone, 6 Grain Temp Guard® Alarm HT

- 45,000 to 51,000 bushel bin: 1 EndZone, 7 Grain Temp Guard® Alarm HT

- 52,000 to 59,000 bushel bin: 1 EndZone, 8 Grain Temp Guard® Alarm HT

EndZone Install Instructions

What Our Customers Say

🌾 The EndZone moisture management system has revolutionized the way I monitor moisture levels in my grain bins.

🚚 Just like I would never buy a truck without a backup camera again, the EndZone and Grain Temp Guard monitors have become essential tools for me.

👴 As I grow older and ladders seem to get taller, the EndZone system makes it so much easier for me to monitor the grain from the ground level, providing a more accurate picture of what’s happening in the bin.

☀️ Whether it’s summer dry-down for rice or fall rehydration for soybeans and corn, the EndZone system helps me manage moisture levels with precision.

🌽 Overall, the EndZone moisture management system is an excellent tool that ensures the best crop quality and helps maximize profitability at sale.

The Grain Temp Guards® that I have, I put on a couple of my smaller bins. It is a more cost-effective way of maintaining the temperature of my soybeans. I have the Alarm HT which tells me the temperature and humidity. It comes with a nice chart to tell me where the grain moisture level is at. This has really worked well for me this year. How this Alarm HT works for me is simple and straightforward. I put in the parameters on where I want the temperature and humidity. The Alarm HT would tell me if the grain got too high or too low depending on what I was trying to do. This year I was trying to dry the grain down and maintain it. When the weather warmed up the Alarm HT monitored the temperature so my fans did not run unnecessarily. Also if there were times of the year where it did spike a little bit, the Alarm HT was able to quickly notify me of the problem. Having a little more information really helped us understand and see the patterns. When the humidity gets higher and the temperature goes up we can almost know which fan was going to need to be turned on. It’s for your own information, you’re not just trusting; you learn a little bit more about maintaining the grain. I do anticipate putting Grain Temp Guards® on all my bins. I don’t think I would want to go back to not having them. It’s just the peace of mind that I’m maintaining my grain properly, especially when you’re considering moisture discounts and spoilage problems when selling grain.

Grain Temp Guards® seem very effective and I’ve looked at other systems, the price points are not justifiable with smaller bins. This is a good way to take advantage of the same technology with a better price point.

The End Zone and Grain Temp Guard have been a game changer for storing grains. The best thing is when storing wheat, they make us money and save me time by adding moisture back and helps us from over drying corn. When wheat that’s going into storage over 100° and 7% to 8% moisture the End Zone helps cool the grain overnight and also adds humidity back into the bins. The best part is that I no longer have to go manually start the fans in the evening and hurry back to the bins in the morning to shut the fans off before it gets too hot out. I just set the temperature and humidity parameters and the fans turn on when needed and shut off when outside the parameters. So, we save money by only running the fans when conditions are ideal. The only key is to make sure that you leave room on the top of your grain bin for the wheat to expand. We also use The Grain Temp Guard when storing other commodities such as corn and buckwheat on the opposite end of the spectrum it helps us from over drying them. I like being able to see the humidity and temperatures at the top and the bottom of the bins. When using the bin heaters, I then can see how the temperature are changing throughout the bin. The Grain Temp Guards also help me monitor for hot spots. Each week I record the numbers so I can see if there are any changes I need to be concerned about. AIl I can say is I would highly recommend The End Zone and The Grain Temp Guards they paid for themselves in the 1st seasoning of having them.

This is the first year that we did not have a spoilage issue coming into the spring season due to using the Grain Temp Guards®. We have been able to monitor what was going on in the bins before it actually went bad. By being able to watch the temperature and humidity in the bins, we were able to harvest and put our grain into the bins wetter than what we were doing blindly before…. I felt more comfortable being able to watch what was going on. I know some guys who have other versions but dollar wise Grain Temp Guard® seems to be the more doable for a multi-bin situation.

I have the Farm Shop, Grain Temp Guard alarm HT and I religiously check them weekly. It will tell you right away if the temp is going up, or the humidity is changing(moisture migration) and you need to run the fans. I’ve been doing this for 40 years and as you get older it gets harder to climb the bins. With the Grain Temp Guard system, I can stand on the ground, read what is going on! I don’t have to worry about frost, ice, rain; I can stand on the ground, read the monitor, it tells you what is going on and you do what you have to do!