PROTECT YOUR HARVEST

About Grain Temp Guard

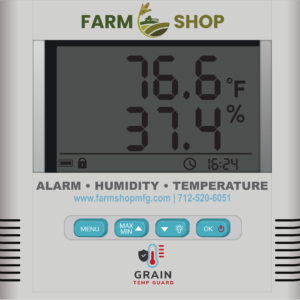

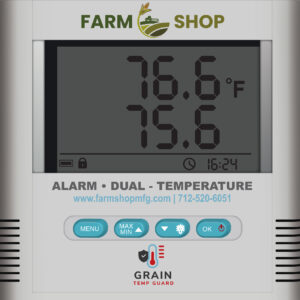

The Grain Temp Guard Humidity-Temperature system is ideal for monitoring higher moisture grains or grain you are conditioning. Track grain conditioning with the humidity reading and data charts from our resources page. High and low temp/humidity warnings may be set independently on each function. Audible and visual alarm sounds when detecting changes in target temperature/humidity. The Grain Temp Guard Dual Temperature System is ideal for monitoring conditioned grains. Measure temperature in two distinct locations. High and low temp warnings may be set independently on each probe.

Why use Grain Temp Guard

Temperature is the best indicator of grain quality. When there’s a significant drop in grain quality, there’s always an abnormal increase in grain temperature. Excessive moisture, high temperature, and poor grain conditions often lead to trouble in stored grain. The importance of monitoring these aspects is compounded by the fact that grain is now stored longer and in larger bins than before. Harvesting and storing grain at a higher moisture content and the higher cost of handling and moving grain also increase the risk of problems. By monitoring temperature accurately, the grain only needs to be turned when required. This makes aeration systems more efficient.

Grain is a perishable commodity and will only last so long. It loses its quality faster as temperature and moisture increase. Monitoring temperature and humidity helps grain maintain its market-grade status for a longer period of time.

On the opposite end of the spectrum, temperature and humidity monitoring can prevent the overuse of aeration systems that leads to shrinkage. Overdrying by 2-4% can cause significant bushel loss per bin resulting in thousands to tens of thousands of dollars in lost profits.

How Grain Temp Guard Works

Available in Dual-Temp or Humidity-Temp.

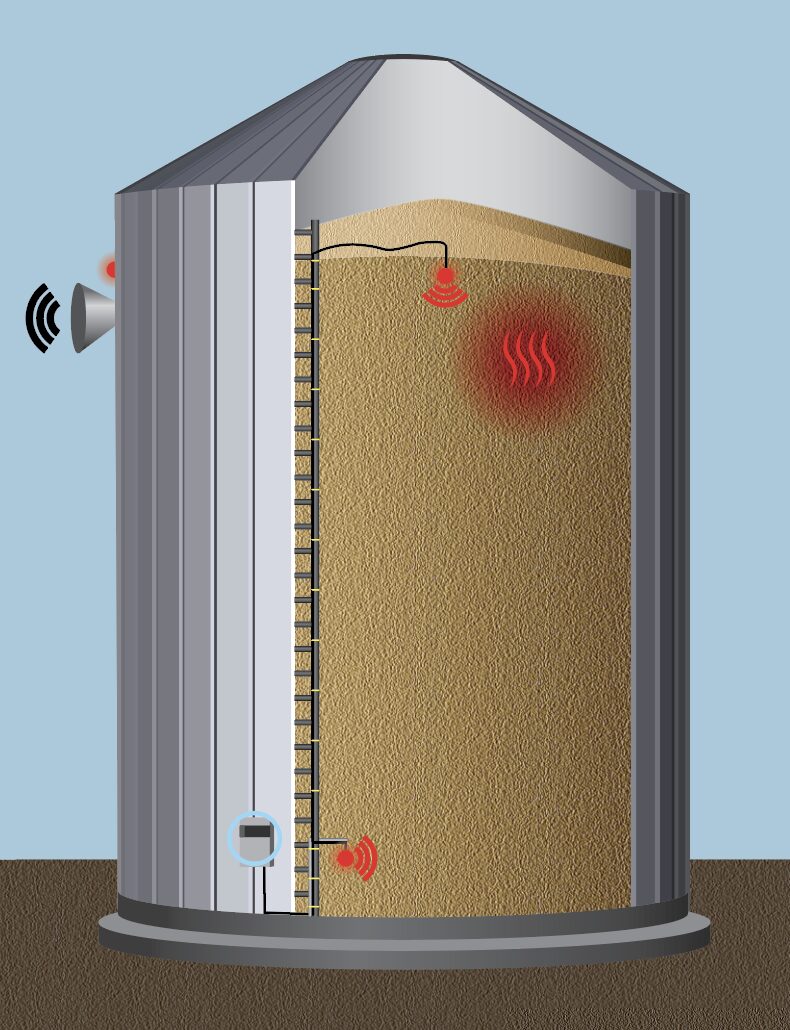

Detect hot spots or moisture buildup.

Alerts you of readings outside normal range.

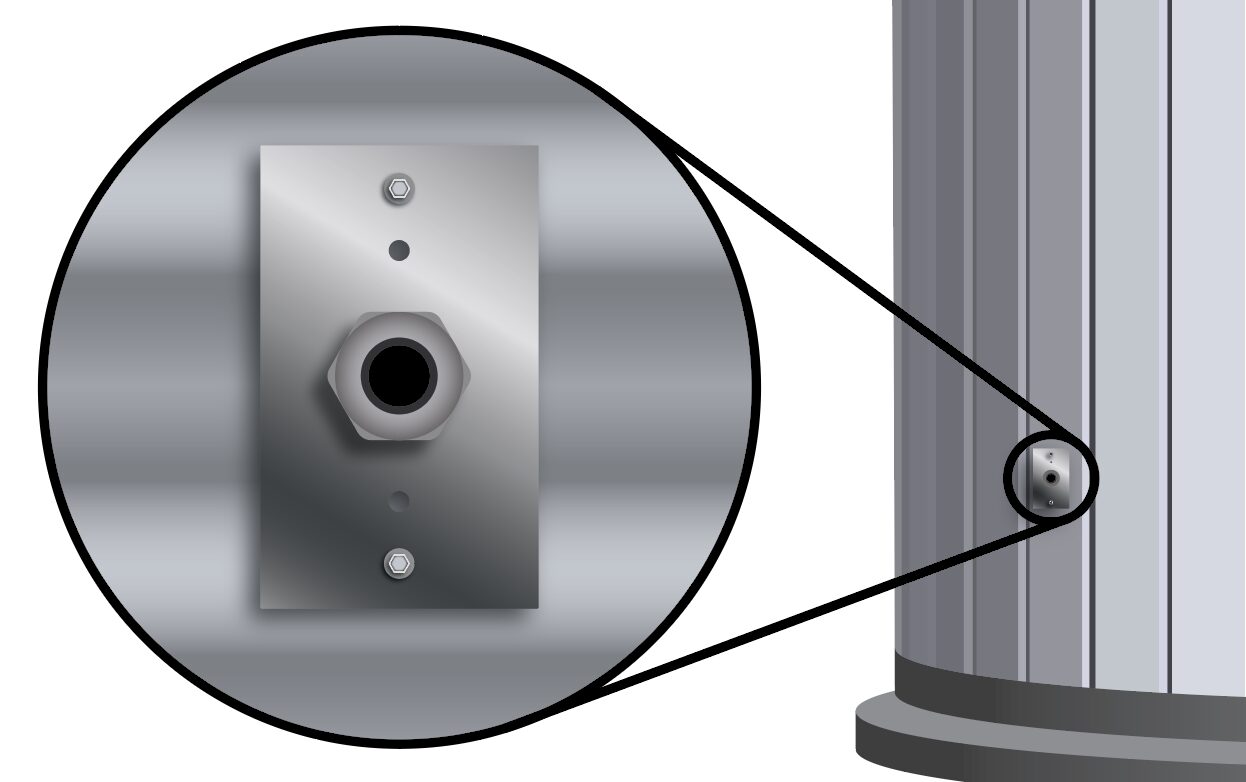

Sidewall and door mounting kits available.

DESIGNED BY FARMERS FOR FARMERS

The Grain Temp Guard Difference

Our Grain Temp Guard bin monitoring system is a must-have for conditioning grain. Because grain is a good insulator, the center of the grain bin retains heat longer. Moisture migration is caused by differences in grain temperature within the bin. In the fall, the cold air on the outside of the bin moves the warmer air inward and eventually upward to the top of the bin. It encounters the cold air at the top of the bin and causes condensation and crusting at the top of the grain. In the spring and summer, the opposite is true, and condensation and spoilage occur at the bottom of the bin. Temperature monitoring helps maintain even temperature, preventing moisture migration.

Overdrying corn or beans reduce your product by 1.5% for each 1% moisture loss.

That’s money out of your pocket:

- $1650 for corn

- $3850 for beans

Money spent to put an alarm HT probe in the top (this can be placed after the bin is full) of the bin and one in the bottom would go a long way to help a farmer get control of this.

PROTECT YOUR HARVEST WITH

Grain Temp Guard

-

Grain Temp Guard – Alarm HT – Generation 2

$499.00 -

Grain Temp Guard Side Wall Mounting Kit

$22.99 -

Grain Bin Moisture Management Package

$2,822.00 – $7,131.00 -

Grain Temp Guard Probes – Alarm HT

$75.00 – $220.00 -

Grain Temp Guard Probes – Alarm DT

$50.00 – $150.00 -

Grain Temp Guard Lithium 9V Battery

$10.00 -

Grain Temp Guard Door Mounting Kit

$15.99 – $25.99 -

Grain Temp Guard – 1st Generation

$275.00 – $350.00 -

Grain Temp Guard Dual System

$999.00 – $999.99

Installing Grain Temp Guard

- Identify the location on the bin where you would like to position the unit. Do not position the unit in a location on the south or southwest side of the bin where the afternoon sun will shine directly at the electronics (direct sunshine into the polycarbonate clear cover will result in a greenhouse type solar heating and can increase the internal temperature by 35°F to 50°F as compared to the outside environment, thereby damaging the electronics). If you position the unit on the south or southwest side, it needs to be in a shaded area. Failure to do this will damage the LED screen and void the warranty. Additionally, you may want to consider an area in proximity to the internal ladder, as we normally use this structure to zip-tie the cable to. Any loose cable on the outside of the bin needs to be zip-tied to a structure such as conduit, ladder rails, etc. to prevent wind whipping and chafing of the insulation. It is not recommended that you have long lengths of exposed cable on the outside of the bin. If this is necessary, it is recommended that you place the cable inside a conduit.

- Mount the case to the bin; mounting flanges may be adjusted for the best match to a corrugation rib. Remove the gasket from the self-tapping screws, insert the screw through the flanged hole, and replace the gasket. The gasket needs to be against the bin to prevent leakage.

- The probe will require a three-quarter-inch hole through the corrugation.

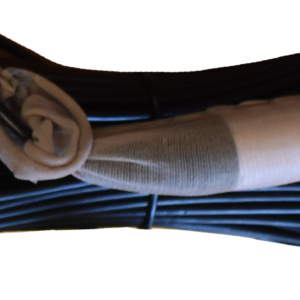

- Suspend any loose cable within the bin by zip-tying it frequently to the conduit or sliding it through conduit.

- A short arm can be made to suspend the lower cable 36 to 48 inches from the ladder by bending a piece of re-rod into an L and positioning the long leg inside a ladder angle iron in the short leg sticking out no more than a foot. Too long of a lever will be ripped off by corn pressure. The long leg should pass behind two ladder rungs and in front of the third (see the above graphic) to ensure the mechanism functions properly. Zip-tie the long leg of the L frequently or bolt it to ensure strength.

- Zip-tie the short cable to the L and zip tie any excess cable in a loop firmly to the ladder structure.

- Extend the long cable up along the ladder making a small loop of the excess cable and securing it to the top of the ladder or on a hook just below the access hatch. When the bin is full you will take this cable, uncoil it, and position it in the grain where you would like to monitor the temperature or temperature – humidity.

The intent of this installation is to keep everything simple and cost-effective. You may at your own discretion provide a more complex installation.

Complete Moisture Management System for a large bin.

Wires can be run into the bin and then through conduit to protect the moisture management system.

Wires can be run though conduit and then attached to rebar to keep everything organized.

Rebar can be used to place sensors throughout the bin at appropriate levels.

Mount lower probe to rebar and place 2ft off ground, attaching to ladder.

Probe for top of bin can be coiled when not in use.

Attach probe to rebar to extend into bin. (Attach to bottom of bar to avoid probe damage)

Attach probe to rebar to extend into bin.

pair with endzone

Moisture Management System Layout

System and probe placement per bin size

- 3,000 to 6,000 bushel bin: 1 EndZone, 1 Grain Temp Guard® Alarm HT

- 7,000 to 15,000 bushel bin: 1 EndZone, 2 Grain Temp Guard® Alarm HT

- 16,000 to 23,000 bushel bin: 1 EndZone, 3 Grain Temp Guard® Alarm HT

- 24,000 to 30,000 bushel bin: 1 EndZone, 4 Grain Temp Guard® Alarm HT

- 31,000 to 37,000 bushel bin: 1 EndZone, 5 Grain Temp Guard® Alarm HT

- 38,000 to 44,000 bushel bin: 1 EndZone, 6 Grain Temp Guard® Alarm HT

- 45,000 to 51,000 bushel bin: 1 EndZone, 7 Grain Temp Guard® Alarm HT

- 52,000 to 59,000 bushel bin: 1 EndZone, 8 Grain Temp Guard® Alarm HT

What Our Customers Say

🌾 The EndZone moisture management system has revolutionized the way I monitor moisture levels in my grain bins.

🚚 Just like I would never buy a truck without a backup camera again, the EndZone and Grain Temp Guard monitors have become essential tools for me.

👴 As I grow older and ladders seem to get taller, the EndZone system makes it so much easier for me to monitor the grain from the ground level, providing a more accurate picture of what’s happening in the bin.

☀️ Whether it’s summer dry-down for rice or fall rehydration for soybeans and corn, the EndZone system helps me manage moisture levels with precision.

🌽 Overall, the EndZone moisture management system is an excellent tool that ensures the best crop quality and helps maximize profitability at sale.

The Grain Temp Guards® that I have, I put on a couple of my smaller bins. It is a more cost-effective way of maintaining the temperature of my soybeans. I have the Alarm HT which tells me the temperature and humidity. It comes with a nice chart to tell me where the grain moisture level is at. This has really worked well for me this year. How this Alarm HT works for me is simple and straightforward. I put in the parameters on where I want the temperature and humidity. The Alarm HT would tell me if the grain got too high or too low depending on what I was trying to do. This year I was trying to dry the grain down and maintain it. When the weather warmed up the Alarm HT monitored the temperature so my fans did not run unnecessarily. Also if there were times of the year where it did spike a little bit, the Alarm HT was able to quickly notify me of the problem. Having a little more information really helped us understand and see the patterns. When the humidity gets higher and the temperature goes up we can almost know which fan was going to need to be turned on. It’s for your own information, you’re not just trusting; you learn a little bit more about maintaining the grain. I do anticipate putting Grain Temp Guards® on all my bins. I don’t think I would want to go back to not having them. It’s just the peace of mind that I’m maintaining my grain properly, especially when you’re considering moisture discounts and spoilage problems when selling grain.

Grain Temp Guards® seem very effective and I’ve looked at other systems, the price points are not justifiable with smaller bins. This is a good way to take advantage of the same technology with a better price point.

The End Zone and Grain Temp Guard have been a game changer for storing grains. The best thing is when storing wheat, they make us money and save me time by adding moisture back and helps us from over drying corn. When wheat that’s going into storage over 100° and 7% to 8% moisture the End Zone helps cool the grain overnight and also adds humidity back into the bins. The best part is that I no longer have to go manually start the fans in the evening and hurry back to the bins in the morning to shut the fans off before it gets too hot out. I just set the temperature and humidity parameters and the fans turn on when needed and shut off when outside the parameters. So, we save money by only running the fans when conditions are ideal. The only key is to make sure that you leave room on the top of your grain bin for the wheat to expand. We also use The Grain Temp Guard when storing other commodities such as corn and buckwheat on the opposite end of the spectrum it helps us from over drying them. I like being able to see the humidity and temperatures at the top and the bottom of the bins. When using the bin heaters, I then can see how the temperature are changing throughout the bin. The Grain Temp Guards also help me monitor for hot spots. Each week I record the numbers so I can see if there are any changes I need to be concerned about. AIl I can say is I would highly recommend The End Zone and The Grain Temp Guards they paid for themselves in the 1st seasoning of having them.

This is the first year that we did not have a spoilage issue coming into the spring season due to using the Grain Temp Guards®. We have been able to monitor what was going on in the bins before it actually went bad. By being able to watch the temperature and humidity in the bins, we were able to harvest and put our grain into the bins wetter than what we were doing blindly before…. I felt more comfortable being able to watch what was going on. I know some guys who have other versions but dollar wise Grain Temp Guard® seems to be the more doable for a multi-bin situation.

I have the Farm Shop, Grain Temp Guard alarm HT and I religiously check them weekly. It will tell you right away if the temp is going up, or the humidity is changing(moisture migration) and you need to run the fans. I’ve been doing this for 40 years and as you get older it gets harder to climb the bins. With the Grain Temp Guard system, I can stand on the ground, read what is going on! I don’t have to worry about frost, ice, rain; I can stand on the ground, read the monitor, it tells you what is going on and you do what you have to do!