A Farmer’s Guide To Grain Storage Best Practices

Proper grain storage is necessary for maintaining the quality and value of your hard-earned crops. Whether you’re a seasoned farmer or just starting out, understanding the best practices for grain storage can make a significant difference in your operation’s long-term success. This comprehensive guide will explore key considerations and strategies to ensure your grain storage is optimized for maximum efficiency and protection.

The Importance of Grain Storage

Before delving into best practices, it’s crucial to understand why proper grain storage is essential. Grain storage serves multiple purposes:

- Preservation: Adequate storage helps maintain the quality and nutritional value of grains, reducing the risk of spoilage and loss.

- Market Flexibility: Effective storage allows farmers to store grains until market conditions are favorable, maximizing profitability.

- Risk Management: Farmers can minimize the risk of crop damage and financial loss by mitigating factors such as moisture and pests.

Understanding Grain Moisture Content

Maintaining the appropriate moisture levels stands out as a pivotal factor in the success of grain storage. Grains stored at the right moisture level are less susceptible to spoilage, mold, and insect infestations. Closely monitor your grain’s moisture content and adjust storage conditions accordingly. Invest in reliable moisture testing equipment to ensure accurate readings.

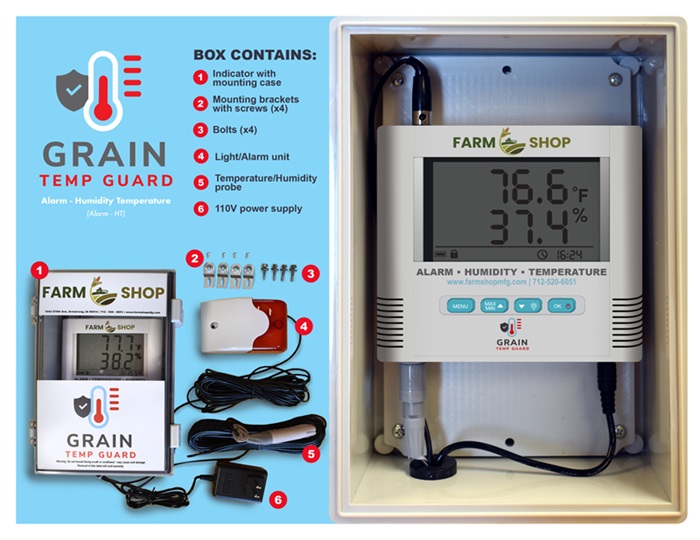

Investing in Grain Temperature Monitoring Systems

One of the cornerstones of effective grain storage is monitoring temperature. Fluctuations in temperature can accelerate spoilage and mold growth, leading to significant losses. Investing in grain temperature monitoring systems offered by Farm Shop MFG allows farmers to track temperature variations in real time and take proactive measures to prevent spoilage. These tools track and monitor the temperature of stored grain in agricultural facilities such as silos, bins, and warehouses. They consist of sensors placed at various locations within the grain storage structure, which continuously measure the temperature of the grain mass. The data collected by these sensors is then transmitted to a central monitoring unit, where it can be analyzed in real-time.

Optimizing Storage Conditions

Maintaining optimal storage conditions is paramount to preserving grain quality. Here are some key factors to consider:

- Ventilation: Adequate airflow is essential for preventing hot spots and maintaining uniform temperature distribution. Proper ventilation systems, including fans and vents, help achieve this.

- Rodent and Pest Control: Implement measures to prevent rodents and pests from accessing stored grains. This practice may include sealing entry points, using traps, and employing grain protectants.

Utilizing Proper Storage Containers

Selecting suitable storage containers plays a pivotal role in safeguarding grain quality. While traditional silos remain popular, newer alternatives such as grain bags and bunkers offer flexibility and cost-effectiveness. Whichever option you choose, ensure containers are clean, dry, and properly sealed to prevent moisture ingress and pest infestation.

Implementing Effective Handling Practices

Proper handling during both storage and transportation is essential for preserving grain quality. Avoid excessive handling and minimize mechanical damage using gentle equipment such as conveyors and augers. Additionally, regularly inspect storage containers for signs of damage or wear and repair any issues promptly.

Regular Maintenance and Inspection

Regular maintenance and thorough inspection are crucial to ensuring the effectiveness of your grain storage system. Schedule routine checks to identify any potential issues such as leaks, damage, or equipment malfunction. Addressing problems can promptly prevent costly repairs and mitigate the risk of crop loss.

Conclusion

When it comes to grain storage, maximizing your capacity is essential for efficient operations. Farm Shop MFG offers a range of innovative solutions to help you optimize your storage space. Our Grain Temp Guard lineup, featuring the next generation of bin monitors, can help you maintain precise control over the conditions within your storage facilities. Besides grain monitoring systems, we also supply germinator closing wheels that significantly ensure optimal seed germination and plant growth.